Description

TITAN Lithium 12.8V 120Ah Battery

12.8V | 120Ah | 1,536Wh

355mm long x 175mm wide x 190mm high

Perfect for those looking for the highest tier of lithium battery for use in camping, marine or renewable storage, our 120Ah lithium is our answer to the standard 110Ah lithium battery from others but packs a bigger punch with a larger capacity, higher quality cells, Bluetooth at no extra cost and an uprated BMS. This battery is still 190mm tall, so can fit under seats if required, plus can be mounted on its side if you need it 175mm in height.

This battery is also perfect for those who need a 12V power source in a condensed and lightweight package (not for engine starting, though).

TITAN LiFePO4 batteries are inherently safe both chemically and thermally, and do not use rare materials like Cobalt or Nickel. In return, we get a slightly lower cell voltage of 3.2V per cell (4x cells = 12.8V), and a lower energy capacity compared to NMC (Lithium nickel manganese cobalt – the cells used in EVs), however LiFePO4 are much more stable at a chemical level, and have much higher lifespans – our batteries can last between 2,500 and 10,000 cycles (depending on use) – NMC is typically 1,000 to 2,500 cycles.

The omission of Cobalt vastly reduces the chance to start thermal runaway. Many now consider LiFePO4 to be safer than lead-acid thanks to their stability and internal control. They can be used in any orientation (e.g. on its side), although on its base will give the best performance. They contain absolutely no acid, generate no gas emissions and are recyclable.

TITAN batteries can be cycled (1 discharge + 1 charge = 1 cycle) between 2,500 to 10,000 times. The amount of cycles corresponds to how deep the discharge is – this is referred to as DOD; Depth of Discharge). If you discharge 100% of the capacity every time you use the battery, it can do this 2,500 times before needing to be replaced. The less capacity used, the higher the cycle life.

In terms of measurable life: if you discharged this battery 100% every day of the year – 2,500 cycles ÷ 365 days = 6.8 years expected lifespan

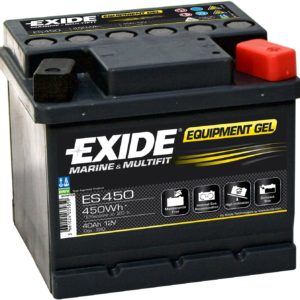

To put this into perspective, the highest quality lead-acid gel battery (gel has the best cycle count of lead-acid) can do 350-400 cycles at 80% DOD.

To get the same capacity in lead-acid, you would need two massive, heavy 142Ah batteries (Exide ER650) in a parallel connection to make 284Ah. Just one TITAN 120Ah can save a huge amount of space, weight, extra wiring and has the added benefit of no gassing, so can be placed anywhere.

To compare accurately, we only use Wh (Watt Hour) capacity ratings – Ah (Amp Hour) ratings unfortunately do not take battery chemistry differences into account: TITAN lithium batteries use 100% of their capacity (~90% with Gel, ~75% AGM & ~60% traditional flooded lead-acid). This coupled with lithium’s inherent energy density, means our batteries have over double the useable capacity compared to lead-acid batteries.

Our most asked question – can lithium replace your current lead-acid battery? TITAN lithium batteries are designed as a direct replacement of lead-acid batteries with no need for new equipment. For more detailed information, please check out our FAQs

Our lithium batteries are for running equipment only (i.e. deep cycle use) – they are not designed for engine starting.

All TITAN lithium batteries use the highest quality lithium cells. In doing so, we can achieve better performance, higher BMS thresholds and a better overall lifespan compared to others.

We use prismatic lithium cells (they look like a long rectangle) rather than cylindrical cells. Prismatic cells are more expensive and harder to make than cylindrical, but the benefit is a higher quality, higher capacity and potent battery. As all battery cases are squares, our cells fill out all available space within which allows us to boast higher capacities over other brands.

Cylindrical cells will waste a fair amount of internal space as circles put together will always have a gap, and are far harder to repair as they use a lot of spot welding in their design.

All TITAN batteries have their own BMS built-in. A Battery Management System (BMS) is a circuit board that is mounted on top of the internal cells inside the battery which is connected in between the cell terminals, and external battery terminals. The BMS controls and monitors everything with split second accuracy to ensure the battery cannot be damaged through normal day to day use. TITAN BMS currently has a market leading 11 protections built-in e.g. over discharge protection, over voltage, under voltage, temperature protection and short circuit protection to name a few.

All protections are temporary and are designed to self-reset or reset when the battery is put on a charger.

TITAN lithium’s BMS has one of the highest rated BMS allowances on the market thanks to the use of the best quality materials and internal workmanship.

The same capacity in a single lead-acid battery weighs a massive 50Kg (Exide AGM EP1500), and is over twice the physical size. A 37Kg weight saving can mean a huge difference when traveling abroad, as well as offering better MPG on vehicles.

Perfect as a drop-in replacement for lead-acid batteries, our high-performance copper terminals ensure the best electrical performance while inherently providing corrosion-free contact.

Need bolt terminals instead? No problem – we can provide high-quality, hot stamped brass M8 nut & bolt adapters free of charge (just leave us a note at checkout).

Despite its high initial cost, TITAN lithium is cheaper than its lead-acid counter parts over its lifespan. Our design life is 10 years – rounded up this battery costs £800 or £80 a year. The closest capacity equivalent in lead-acid is the Exide AGM EP1500 with a design life of 4 years – currently around £385 or £96 a year (replacing the battery at the 4 year mark). This equates to over £160 in savings, plus all the benefits of a lighter, smaller and more efficient battery.

While the design life of TITAN Lithium is 10 years, we expect the average user to reach 15-20 years, making it an even better investment. The realistic average life of Lead-acid is 3-5 years.

Thanks to our 99% efficiency rating, TITAN batteries utilises incoming charge energy with little waste; making them a perfect partner for solar chargers. Our batteries can accept extremely high charging amps which means they can be charged extremely quickly – from 0% to 95% in less than 2 hours (when charged over 100Amps).

This efficient charging means TITAN batteries are also perfect for home solar storage (although we’d recommend looking at our higher voltage batteries for better BMS efficiency).

Due to the potential extreme difference in electrical demand per user, all of our batteries include a full 6 year or 2,500 cycle warranty – whichever comes first. The warranty covers all components against premature failures caused by manufacturing faults – for more information, please click here

If anything does fail prematurely, we aim to repair or replace individual problem components rather than replace the whole battery. Doing this also allows us to reduce our carbon impact and reduce waste. As we are battery specialists (we used to make batteries in the 1950s), we are adept at any and all repairs should they arise – we do ask customers to leave the repairs to us; cells and BMS’s are proprietary in design.